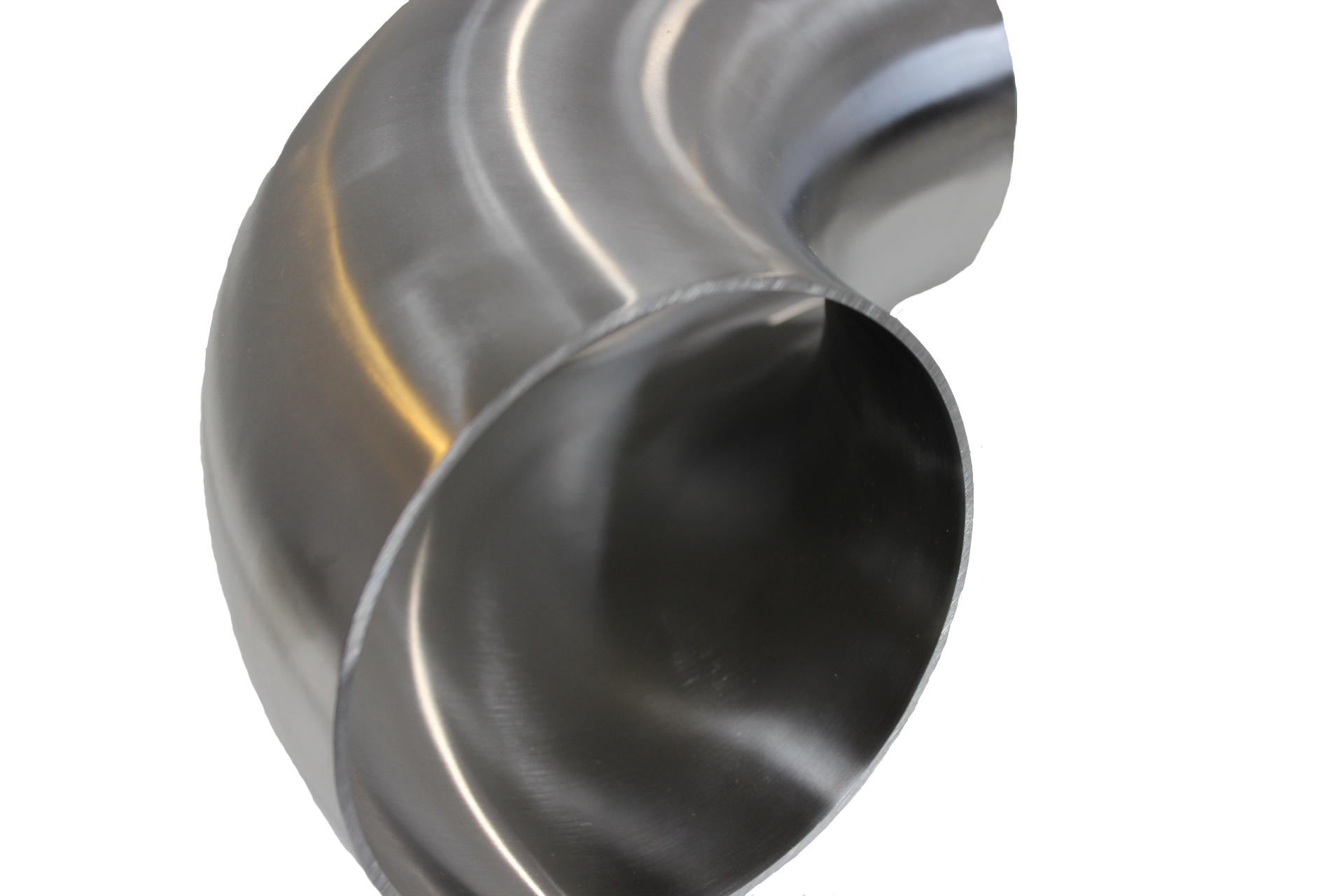

### Mechanisms of Low-Temperature Toughness in ASTM A333 Steel Pipes: Orchestrating Carbon Equivalent, Rare Earth Treatments, and Tailored Heat Processing for Charpy Resilience at -forty five°C and Beyond

In the shadowed geographical regions in which industrial lifelines pulse simply by arctic tundras or cryogenic vaults, metal pipes needs to defy the brittle embrace of subzero ferocity—temperatures plunging to -45°C, -101°C, or even the liquid nitrogen chill of -196°C—with out fracturing under the hammer of have an effect on. Enter ASTM A333, the sentinel preferred for seamless and welded carbon and alloy metal pipes engineered for such low-temperature odysseys, from LNG vendors reducing polar seas to ammonia plants buzzing in Siberian isolation. This specification, a cornerstone of ASME Boiler and Pressure Vessel Code Section II, mandates now not simply persistence but a symphony of longevity: the Charpy V-notch (CVN) affect try out, that venerable pendulum strike simulating fracture initiation, should soak up at the least 27 J (universal of 3 specimens) on the special low temperature, without single importance dipping under 20 J. For Grade 6, the workhorse of the sequence, this gauntlet unfolds at -46°C; Grade 1 at -29°C; Grade 3 at -one hundred and one°C; and the exotica of Grade nine at -196°C, every single calibrated to thwart the ductile-to-brittle transition temperature (DBTT) in which face-based cubic grace yields to body-situated cubic rigidity. Yet, how does this resilience emerge from atomic chaos? It's no coincidence of metallurgy yet a planned choreography: curtailing carbon similar (CE) to tame hardenability, infusing rare earth components (REEs) to sculpt inclusions into benign spheres, and wielding normalizing or quenching-and-tempering (Q&T) like a sculptor's flame to refine grains and mood stages. These levers, intertwined, suppress cleavage fracture— that transgranular snap along a hundred planes in ferrite—whereas amplifying power dissipation thru twinning, dislocation pile-ups, and microvoid coalescence, guaranteeing CVN energies crest the necessary plateau while entropy whispers of brittleness.

The peril of low temperatures lies in steel's thermodynamic betrayal: as Kelvin plummets, thermal activation wanes, Peierls obstacles stiffen dislocations, and the stack-fault vigour in austenite (if any lingers) favors martensitic shards over ductile flow. Plain carbon steels, with their Widmanstätten ferrite webs, shatter like glass at -20°C, their CVN plunging from 200 J upper-shelf bounty to a meager 10 J inside the scale back shelf, in keeping with the vintage S-curve of transition behavior. ASTM A333 counters with ferritic alloys of surgical precision—low-carbon (zero.05-zero.30 wt% C for maximum grades), manganese-boosted (0.40-1.60 wt% Mn) for good-answer strengthening, and whispers of Ni (as much as 3.50 wt% in better grades) to stabilize austenite remnants or refine ferrite nucleation. But the linchpin? Microstructural mastery, wherein toughness T ∝ (d^-half of) by the use of Hall-Petch (d=grain length), amplified by way of inclusion morphology and phase homogeneity, to depress DBTT underneath service minima and maintain absorbed calories E_abs = ∫ σ dε with the aid of the transition knee. For A333 Grade 6, this yields a DBTT around -60°C, with CVN at -46°C normally exceeding 50 J in optimized heaps, a 2x margin over spec.

Foremost among controls is carbon equal, that composite metric CE = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15 (IIW formula), a proxy for weldability and hardenability. High CE (>zero.forty) invitations martensitic islands for the time of cooling, brittle at low temps as a consequence of their tetragonal distortion and carbon supersaturation, which spike the important stress for dislocation emission σ_c ∝ √(E γ / (1-ν) b), in which γ=surface power ballooning inside the cryogenic regime. In A333, CE is throttled below 0.40 for Grade 6 (everyday 0.25-zero.35), carried out by using lean C (≤0.30%) and balanced Mn (zero.29-1.06%), minimizing the martensite soar (Ms) temperature while fostering acicular ferrite—fine, interlocking laths that deflect cracks by using boundary scattering, in step with the Orowan type of precipitation strengthening. This is simply not mere subtraction; this is strategic alloying. Manganese, at 0.five-0.eight wt%, walls to austenite limitations throughout transformation, retarding ferrite nucleation on inclusions and promoting intragranular acicular versions over coarse polygonal ones, slashing cleavage side sizes from 50 μm to <10 μm and elevating CVN by means of 40-60 J at -forty five°C. Silicon (≤zero.forty%) aids deoxidation devoid of extra brittleness, whereas phosphorus and sulfur caps (≤0.1/2% both) minimize intergranular embrittlement, as P segregates to boundaries, lowering cohesive electricity and fostering mood embrittlement.<p>

Empirical alchemy shines in construction: steelmakers like the ones crafting A333 for ExxonMobil's arctic lines refine CE because of ladle metallurgy—argon stirring to homogenize, Ca-Si injections for sulfide sphericity—yielding billets with CE gradients four hundred°C making certain no martensite; at CE=0.forty five, bainite surges to 30%, DBTT emerging 20°C and CVN at -45°C cratering to fifteen J. Weldability bonuses abound—low CE quells HAZ hardening, conserving transverse sturdiness imperative for girth welds in pipeline strings. In sour carrier consistent with NACE See Pricing MR0175, this handle doubles SCC resistance via avoiding demanding microstructures more likely to hydrogen uptake, the place H atoms pin dislocations, elevating local stresses to gigapascal spikes.

Yet, CE on my own is a blunt instrument; input uncommon earth treatment plans, the esoteric guardians of inclusion morphology. REEs—cerium (Ce), lanthanum (La), neodymium (Nd)—dosed at zero.half-0.03 wt% throughout the time of ladle refining, transmute deleterious stringers into globular allies. Conventional deoxidizers spawn elongated MnS inclusions, MnS (Al2O3) composites that act as delamination nuclei, channeling cracks alongside rolling planes and slashing transverse CVN through 70% at low temps, as consistent with Gurland's mannequin of void coalescence. REEs, with their outsized atomic radii (1.18 Å for Ce vs. 1.26 Å Fe), preferentially bind sulfur via Ce2S3 or La2S3, forming cuboidal or spherical precipitates (part ratio <2:1) sturdy to 1400°C, dispersed at 10-50 μm spacings. These "RE-sulfides" not in basic terms blunt crack tips—R-curve increasing by way of plastic quarter enlargement—however inoculate ferrite nucleation during transformation, refining grains by means of 20-30% by means of Zener pinning, F_z = 3f γ / r (f=quantity fraction ~0.001, γ=zero.8 J/m², r=1 μm), depressing DBTT 15-25°C.<p>

In A333 contexts, REEs shine for cryogenic grades like 8 and nine, where Ni (8.40-nine.60 wt%) stabilizes austenite however hazards Widmanstätten part-plates devoid of modification. A POSCO examine on REE-microalloyed LTCS printed zero.01 wt% Ce boosting -196°C CVN from 20 J to forty five J in Grade 9 analogs, by way of 40% denser acicular ferrite packets, both a five-10 μm domain of prime-attitude barriers that zigzag cleavage paths, absorbing electricity by using deflection angles >30°. Mechanisms deepen: REEs scavenge oxygen too, curtailing oxide stringers that anchor cleavage ledges; their oxysulfides (Ce2O2S) display low lattice mismatch (zero.05 wt%) clusters REE phases, coarsening to ten μm and inverting blessings, as a result vacuum induction melting (VIM) titrates precisely, monitored by way of LIBS spectrometry. In welded A333, REEs mitigate liquation cracking in HAZ, preserving fusion line longevity for CVN minima.

Heat healing seals the %, transforming conceivable into pedigree. Normalizing—reheating to 870-920°C (1600-1700°F) for 1 hr/inch thickness, followed by air cooling—erases casting heterogeneities, recrystallizing austenite to ASTM 8-10 grains (15-20 μm), then nucleating superb polygonal ferrite upon crossing the γ→α nose of the CCT diagram. For Grade 6, this yields a microstructure of 80-ninety% equiaxed ferrite (lath width 1-2 μm) with pearlite nodules, where ferrite's bcc lattice, although vulnerable to cleavage, is buffered through grain obstacles that bow out underneath rigidity, consistent with Rice-Thomson criterion for emission, maintaining plastic movement at -forty five°C. Cooling quotes (5-10°C/s) are key: too gradual invites coarse Widmanstätten, DBTT +30°C; too quick, upper bainite with carbide networks that embrittle. A333 mandates normalizing for Grades 1-7, making sure CVN uniformity through-wall, with transverse samples hitting 34 J avg at -46°C in mill trials.

For anxious grades (eight-eleven), quenching and tempering elevates the artwork: austenitize at 900-950°C, water/oil quench to Ms (~three hundred°C), birthing martensite (80-100% in Grade 8), then mood at 550-650°C to partition carbon into ε-carbides, softening to tempered martensite (HV 250-three hundred) laced with retained austenite (five-10 vol%). This TRIP-assisted format—transformation-precipitated plasticity—shines at low temps: less than impression, austenite shears to twinned martensite, soaking up 20-30% added power by way of extent enlargement (four% ΔV), blunting cracks in step with the Eshelby inclusion fashion. Tempering dissolves lath interfaces, curtailing intergranular fracture, while Ni enriches austenite, stabilizing it in step with ΔG = RT ln(x_γ) + interactions, protecting >5% to -a hundred°C. Double normalizing (870°C air cool, then 815°C) precedes Q&T in Grade eight, refining previous-austenite grains to 10 μm, boosting -a hundred and one°C CVN to forty J min. Quench severity issues: for twenty-four" OD pipes, polymer quenches (H=1.5-2.0) avoid distortion while accomplishing via-hardening, monitored through Jominy finish-quench curves predicting hardenability.

Mechanistically, those treatments synergize with CE and REEs. Low CE ensures Ms aligns with quench, keeping off mushy spots; REE inclusions nucleate bainite sheaves at some stage in temper, densifying barriers (ρ=10^14 m^-2) for Hall-Petch fortification with out over-hardening. At -45°C, where thermal activation kT=7 meV pales in opposition t Peierls zero.1 eV, longevity pivots on multiplicity: fine grains multiply deflection websites (N ∝ 1/d), round inclusions void-coalesce submit-yield (in keeping with Thomason variation), and tempered stages allow cross-slip, raising stress hardening exponent n from zero.1 to zero.2. EBSD forensics on A333 Grade 6 reveal 70% high-angle obstacles (>15° misorientation) put up-normalize, channeling cracks into ductile dimples, with fracture surfaces displaying 80% fibrous morphology vs. 20% cleavage in as-rolled relatives.

Quantifying the alchemy, dilatometry lines transformation kinetics: normalizing shifts Ar3 to 720°C, accelerating ferrite burst; Q&T tempers Ms to 250°C, with retained γ fraction f_γ = exp(-Q/RT) in keeping with thermo-Calc. Impact fractography using SEM unveils the payoff: in REE-Q&T Grade 9, dimple depths traditional 5 μm at -196°C, vs. 1 μm in plain versions, correlating to 2x J-necessary upward thrust. Field validations abound—a 2024 Baker Hughes audit on A333 Gr6 for Alaskan gaslines clocked ninety five% CVN compliance put up-normalize, with screw ups traced to CE excursions >zero.38 from scrap variability, rectified via a hundred% PMI sorting.

Challenges persist: segregation bands in thick billets coarsen nearby grains, mitigated by means of comfortable-aid rolling pre-normalize; hydrogen from pickling disadvantages delayed cracking, purged with the aid of vacuum holds. Sustainability arcs too—REE recycling from magnets cuts mining scars, whereas induction normalizing slashes vigour 30% vs. furnace. Future whispers: nano-REE carbides with the aid of cluster deposition, or hybrid Q&T with intercritical anneal for dual-phase ferrite-martensite, pushing -a hundred and fifty°C CVN >one hundred J.

In essence, ASTM A333's toughness is not any monolithic protect but a woven tapestry: CE because the warp of composition, REEs the weft of morphology, heat healing procedures the loom of refinement. Together, they orchestrate a microstructure wherein atoms, chilled yet unchained, use up impact's fury—making certain pipes not just live on however thrive in winter's maw, their Charpy verdicts a resounding confirmation of engineered grace.